The Chemical Engineering Journal provides an international forum for the presentation of original research, interpretative reviews and discussion of new development in chemical engineering. Papers which describe novel theory and its application to practice are welcome, as are those which illustrate the transfer of techniques from other disciplines. Reports of carefully executed experimental work, which is soundly interpreted are also welcome. Within the Chemical Engineering Journal, the Environmental Chemical Engineering section presents papers dealing with topics in environmental chemical and process engineering. Treatment processes, environmental process control and measurement and clean process technology are covered, and papers in which knowledge from other disciplines is integrated with chemical engineering are especially welcome.

The Biochemical Engineering Journal is now published as a separate title. This paper reports the photooxidation of 2,4-dichlorophenoxyacetic acid (2,4-D) in aqueous solution employing hydrogen peroxide and ultraviolet radiation. A kinetic model to represent the degradation of 2,4-D and that of equally toxic intermediate products, such as 2,4-dichlorophenol and chlorohydroquinone , is presented. The model includes the parallel, direct photolysis of 2,4-D and the most important reaction intermediates. The experimental work was performed in a batch, well-stirred tank reactor irradiated from its bottom using a low power, germicidal, tubular lamp placed at the focal axis of a cylindrical reflector of parabolic cross-section. Herbicide degradation initial rates twenty times faster than those obtained employing UV radiation alone were found.

In order to reach more useful conclusions about the ability of the process to reduce the contamination to innocuous final products, simultaneous measurements of the total organic carbon were performed. By application of the kinetic model to the whole set of concentration versus time experimental data, the values of the kinetic parameters were obtained. The model permits a good representation of the reaction evolution in a rather wide range of 2,4-D and H2O2 initial concentrations. The UV/H2O2 process has often been proposed as an effective treatment technology for remediation of colored wastewaters. However, it has frequently been noted that it is not as economically efficient as other treatment technologies.

To limit this drawback as much as possible, an effort to optimize the treatment technology from both the economical and operating points of view is needed.This paper presents a study on determination of cost optimal operating conditions for decoloration and mineralization of C. Dye concentration, hydrogen peroxide concentration, pH, treatment time, and temperature were considered to be influential operating parameters. Cost of electricity, cost of hydrogen peroxide, and cost of water needed to adjust the dye concentration were considered to be relevant operating costs.The presented approach is based on response surface methodology in conjunction with mathematical programming. The results obtained clearly indicate that, in order to assure effective and economically efficient operation, the UV/H2O2 process should be simultaneously optimized from the perspective of both operational and economic efficiency. Chemical engineering is a discipline influencing numerous areas of technology and offers unparalleled opportunities to address grand challenges facing society, such as energy, environment, health, food, manufacturing, among others. On a grand scale, a chemical engineering is an 'enabler' to make things happen efficiently on a massive, industrial manufacturing scale with the best results at the least cost and with the lowest impact on the environment possible.

The inadequacy of worldwide fossil fuel resources, combined with increasing energy demands, encourages global attention to either using alternative energy resources or improving the recovery factor and produce larger quantities from present reservoirs. Among all enhanced oil recovery methods, surfactant injection is a well-known technique that reduces the interfacial tension between oil and water and increases oil production. Despite numerous advantages of using surfactants, there are also a few obstacles like environmental impacts, high cost, effect on humans and other organisms due to toxicological potential, and availability from nonrenewable resources. Biosurfactants are microbial surface-active agents that decrease the surface tension of a liquid phase and the IFT of two diverse phases. Biosurfactants are synthesized by microbes; therefore, various genetic diversities of microorganisms provide the considerable capability to produce new types of biosurfactants, which can develop EOR technology.

The genera Pseudomonas, Bacillus, Sphingomonas, and Actinobacteria are the foremost biosurfactant-producing bacteria. This paper reviews relevant reports and results from various presented papers by researchers and companies on applications of microorganisms and biosurfactant technology with specific emphasis on EOR and MEOR processes, based on recently published articles since 2010 until now. The production of ethyl oleate, by homogenous acid esterification of oleic acid with ethanol, have discussed experimentally and via computational simulation in a plug flow reactor.

An innovative simulation model has developed to predict the esterification reaction performance in an ideal plug flow reactor. The amount of H2SO4 acid catalyst, the initial molar ratio of alcohol to oleic acid, ethanol concentration, reaction temperature, and esterification time have examined their effects on ethyl oleate production and the conversion of oleic acid. Then the simulation extended to examine the esterification reaction kinetics and determine the reaction rate coefficients. The simulation results demonstrate that the increasing of H2SO4 acid, initial molar ratio of ethanol to oleic acid, ethanol concentration, and reaction temperature improved the productivity of the ethyl oleate and reduced the reactor space-time.

The kinetics results illustrated that the reaction sensitivity to the temperature unchanging by using higher ethanol concentration and alcohol to oleic acid initial ratio. This paper presents a bioadsorption study of 67Ga from aqueous solution by solid tea factory waste. The experimental parameters were chosen as temperature, pH, stirring speed, nominal particle size and bioadsorbent dose in the ranges of 10.0–40.0 °C, 2.0–8.0, 300–720 rpm, 0.15–1.4 mm and 1.0–15.0 g/L, respectively.

The most effective parameter was determined to be pH, and then temperature, particle size, and bioadsorbent dose in decreasing order. Fourier transform infrared spectroscopy was performed for the characterisation of the bioadsorption of 67Ga on tea waste. The equilibrium results showed that the data exhibited good agreement with the isotherm models of Freundlich, Halsey, and Handerson and Smith. In thermodynamic analysis, ΔG and ΔH values were determined and their values demonstrated that the bioadsorption process was endothermic and spontaneous. Bioadsorption kinetics analysis proved that the rate corresponded to a pseudo second order model, and that the bioadsorption mechanism is governed by intra-particular diffusion. Discharges of waste containing heavy metals have been a challenging problem for years because of their adverse effects in the environment.

This article provides a comprehensive review of recent findings on bacterial biosorption and their performances for sequestration of HMs. It highlights the significance of HM removal and presents a brief overview on bacterial functionality and biosorption technology. It also discusses the achievements towards utilisation of bacterial biomass with biosorption of HMs from aqueous solutions. This article includes different types of kinetic, equilibrium, and thermodynamic models used for HM treatments using different bacterial species, as well as biosorption mechanisms along with desorption of metal ions and regeneration of bacterial biosorbents. Its fast kinetics of metal biosorption and desorption, low operational cost, and no production of toxic by-products provide attraction to many researchers. Bacteria can easily be produced using inexpensive growth media or obtained as a by-product from industries.

A systematic comparison of the literature for a metal-binding capacity of bacterial biomass under different conditions is provided here. The properties of the cell wall constituents such as peptidoglycan and the role of functional groups for metal sorption are presented on the basis of their biosorption potential. Many bacterial biosorbents as reported in scientific literature have a high biosorption capacity, where some are better than commercial adsorbents. Based on the reported results, it seems that most bacteria have the potential for industrial applications for detoxification of HMs. Within the Chemical Engineering Journal, the Novel Materials for Energy and Advanced Applications section presents papers dealing with different aspects of the preparation and characterization of advanced materials designed for specific applications. Manuscripts dealing with micro- and nano-structured materials and/or describing the preparation of composite and hybrid materials with advanced properites are particularly welcome.

Given the applied character of the CEJ, we will consider manuscripts where specific applications are demonstrated for the materials synthesized. The scope and discipline of Chemical engineering is very broad which includes life sciences, chemistry, new materials and microelectronics, reaction engineering, advanced materials, biochemistry and energy & environment etc. Due to rapid advances in scientific research and industrialization, there is more need of advanced and durable study in chemical engineering field.

The Journal of Advanced Chemical Engineering provides the platform to publish these new ideas. The journal serves to distribute the latest information and new idea in all related fields for effective and rapid communication among the audience which includes engineers, researchers and student. The present work investigates the mechanism of the photocatalytic and adsorptive treatment of an aqueous DNP (2,4-dinitrophenol) solution in an annular-flow reactor installed with a TiO2/AC-PET film .

Unfortunately, the experimental result indicates that it is impossible to correctly measure the time courses of product ion concentrations because they are adsorbed onto or desorbed from AC particles. Therefore, a computer simulation methodology using mathematical models is introduced in order to elucidate the treatment mechanism. Moreover, it is found that the TiO2/AC-PET film can lower the burden of the adsorption of DNP onto AC compared with the AC-PET film because a part of DNP molecules are photocatalytically decomposed and the percentage of this decomposition is increased at a lower linear velocity.

In conclusion, the mathematical model taking into consideration a film-diffusional effect can successfully explain the complicated mechanism of the treatment of an aqueous DNP solution using the TiO2/AC-PET film. Azolla rongpong, a fresh water macro alga, was tested for its ability to remove acid dyes (acid red 88 , acid green 3 , acid orange 7 and acid blue 15 ) separately from aqueous solution. The sorption isotherms, obtained at different ranges of pH (2–3.5) and temperature (25–35 °C), were fitted using Langmuir, Freundlich, Redlich–Peterson and Sips models.

The maximum dye uptake of 83.33 mg/g was obtained for AG3 at optimum conditions of pH (2.5) and temperature (30 °C) according to Langmuir isotherm model. Various thermodynamic parameters such as ΔG°, ΔH° and ΔS° were calculated indicating that the present system was spontaneous and endothermic process. The pseudo-first and -second order kinetic models were also applied to the experimental kinetic data obtained during biosorption of four acid dyes and high correlation coefficients favor pseudo-second order model for the present systems.

Rongpong performed very well in the case of AG3 biosorption compared to other dyes, AG3 was selected as the model dye for examining the potential of A. A glass column (2 cm i.d. and 35 cm height) was used to conduct continuous experiments. The experimental data were analyzed using Bed Depth Service Time and Thomas models and the model parameters were evaluated. Photocatalytic membrane reactors seem to be a very promising method of solving problems concerning separation of photocatalyst as well as products and by-products of photodegradation from the reaction mixture. In the presented studies an anatase-phase TiO2 was applied for degradation of Acid Yellow 36 in the PMR coupling photocatalysis and direct contact membrane distillation .

The effect of different process parameters such as dye concentration, reaction temperature and photocatalyst loading on the effectiveness of degradation of AY36 was investigated. Moreover, in order to compare the effectiveness of AY36 photodegradation during photocatalysis alone and the hybrid process, additional experiments without application of MD were conducted. The addition of TiO2 to a feed did not affect the permeate flux, regardless of the process conditions applied. The flux remained constant and equal to the maximum permeate flux during about 400 h of experiments.

The highest decolorization of AY36 solution during hybrid process was observed at the highest photocatalyst loading applied (0.5 g TiO2/dm3). The increase of the reaction temperature from 313 to 333 K resulted in an increase of the photodegradation rate of AY36. After 5 h of the hybrid process the effectiveness of dye degradation calculated on a basis of AY36 mass in a feed solution amounted to 31, 36 and 42% for the reaction temperatures of 313–333 K.

Similar results were obtained when photocatalysis was conducted in the MD installation but with disconnected MD module. It was found that an improvement of AY36 photodegradation could be achieved by a decrease of initial dye concentration. Comparing the results obtained in a conventional slurry photoreactor and in the PMR and taking into account both, the rate of azo dye degradation and the quality of the product, it could be concluded that more beneficial configuration seems to be the PMR. Austin Chemical Engineering is an open access, peer reviewed, scholarly journal dedicated to publish articles related to original and novel fundamental research in the field of Chemical Engineering. It also provides state-of-the-art reviews on clinical and experimental therapies in chemical Engineering. The Open Chemical Engineering Journal is an Open Access online journal, which publishes research articles, reviews, letters, case reports and guest-edited single topic issues in all areas of chemical engineering.

Bentham Open ensures speedy peer review process and accepted papers are published within 2 weeks of final acceptance. It includes the traditional areas of analytical, inorganic, organic, and physical-theoretical chemistry and newer interdisciplinary areas such as materials science, spectroscopy, chemical physics, and biological, medicinal and environmental chemistry. The Journal welcomes original research contributions from all established areas of chemistry and chemical engineering . Thus high quality research papers or reviews dealing with any aspect of chemistry are welcomed. Chemical, biochemical and process engineering is the application of science, maths and economics in the process of turning raw materials into everyday, and more specialist, products.

Professional chemical engineers design, construct and manage process operations all over the world. Oil and gas, pharmaceuticals, food and drink, synthetic fibres and clean drinking water are just some of the products where chemical engineering plays a central role. E-waste is one of the rapidly growing environmental problems of the world. However, the utilization of e-waste to produce economically viable materials such as mesoporous silica molecular sieves has not been well studied to date. Electronic packaging resins have been used widely in semiconductor industry.

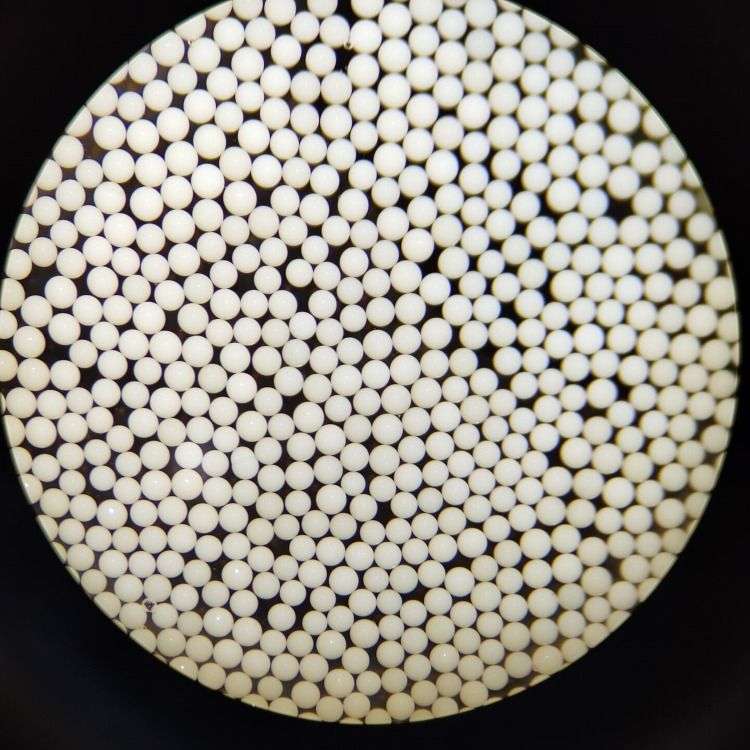

This study uses resin waste from this packaging process as source of Si and cationic surfactant as a template for the synthesis of highly ordered mesoporous silica with large surface area. This investigation reports the effects of various conditions on the self-assembly process of silica including the duration and temperature of the hydrothermal treatment, the molar ratio of water to surfactant, gelation pH, and calcination temperature. Experimental results confirm that MCM-41 with a well-ordered mesostructure is synthesized in strongly basic conditions. The produced silica is free of sodium impurities and the purity is as high as 99.8 wt%.

SEM reveals that the proposed process can be controlled to produce silica particles with various morphologies under acidic or basic media. TEM images clearly illustrate the hexagonal array of uniform meso-channels in the silica materials. The proposed method for synthesizing mesoporous MCM-41 using resin waste provides a viable alternative for recycling and utilizing silicon-containing industrial waste.Highlights► Electronic packaging resin waste is used as Si precursor. ► Cationic surfactant is a template for the self-assembly process of silica.

► MCM-41 shows well-ordered hexagonal mesostructure in strongly basic conditions. He is in the editorial board of "Journal of Hazardous Materials" , "Nanoscience & Nanotechnology-Asia" , "Clean Technologies" . He is reviewer for more than 20 international journals and scientific committees.

Fine Chemical Engineering is a peer reviewed and open accessed journal which is semiyearly published online. The journal publishes original research articles, reviews, short reports, perspectives, case studies, viewpoints and letters. This journal is a scholarly journal maintains high standards of scientific excellence and its editorial board ensures a rapid peer review process with the help of the Editorial Manager System.

Manuscripts are accepted for publication only if at least two reviewers agree on the scientific quality of a submitted manuscript. Abstracts and full texts of all articles published by the Advanced Chemical Engineering Open Access Journal are freely accessible to everyone immediately after publication. The present paper includes studies related to gas/liquid mass transfer process of carbon dioxide in aqueous solutions of glucose and glucosamine. These studies have been carried out employing a cylindrical bubble column, where the gas phase was fed through an only orifice.

The absorption process has been characterized taken into account the influence of gas flow-rate and the liquid phase composition. The interfacial area was determined using a photographic method to calculate the value of the liquid side mass transfer coefficient. Liquid phase composition influences the value of the mass transfer coefficient due to the variation of solution viscosity. Eddy and slip models have been employed to correlate the experimental data of mass transfer coefficient. Anatase titanium dioxide in particle sizes of roughly 0.5–20 μm was prepared from amorphous TiO2 in an aqueous H2O2 solution by heating at 90 °C for 9 h and directly deposited on a PET film.

On the other hand, granular activated carbon particles in sizes of 1–2 mm in diameter were adhesively deposited on a PET film, and their surfaces were also coated with TiO2. The resulting three preparations (TiO2-, AC-, and TiO2/AC-PET films) were set up in an annular-flow reactor to treat aqueous solutions of 2,4-dinitrophenol in a batch-recirculation mode. The rate of DNP adsorption onto the TiO2/AC-PET film without UV irradiation was almost the same as that onto the AC-PET film, indicating that the attraction of DNP to AC was not lowered in the presence of TiO2 film.

Observation of SEM photographs suggests that this result is attributed to the porous structure of the thin TiO2 film covering AC particles. The rate of DNP removal by the TiO2-AC PET film under UV irradiation was 2.9 times higher than that by the TiO2-PET film under UV irradiation, and was 1.1 times higher than the rate of DNP adsorption onto the AC-PET film. The rate of DNP removal by the AC-PET film decreased by 40% after six runs, while that by the TiO2/AC-PET film decreased by 22%. Durable experiments using the TiO2/AC-PET and AC-PET films clarified that the lifetime of the TiO2/AC-PET film is at least two times longer than that of the AC-PET film. This result suggests that DNP molecules are photocatalytically decomposed when passing through the porous TiO2-PET film, which lessens a burden of DNP adsorption on AC.